Tech tips

Is air filter working properly?

How to understand when an air filter doesn’t protect your buggy engine.

Most of the time it’s not easy to explain when the air-filter doesn’t protect your engine.Even using an oiled air filter, foam density might not be optimal to all track “dust-particles” and conditions.

These pictures should give you a clear view of well protected parts (A) and badly protected parts (B). Dust causes loss of performance, tuning issues and decreases the life of the engine.

We recommend you pay extreme attention to this and if needed, change the type of foam density or air filter oil according to track conditions.

Piston (A) shows only the sealing ring above the piston pin hole is “grey” in colour, while the rest of the surface is clean and fuel coloured.

Piston (B) shows almost all the surface is opaque “grey” in colour which means the dust has worn out the piston surface.

Crankshaft (A) shows a shiny surface without any grooves.

Crankshaft (B) shows a surface with grooves, proving the passage of dust.

Picco engine basic settings.

Starting your NEW Picco engine

Start the engine with the factory settings. It is extremely important not to rev the engine too much while running it in. The factory settings are very rich. Run the model on the track for 4 tanks paying extreme attention that the exhaust pipe emits plenty of smoke.

Setting your carburetor (Inspired by Ron Paris)

Carburetor needles setting (on the bench):

- High speed needle / Low speed needle

As you turn the needle clockwise (leaner), less fuel enters the engine. Turning it counterclockwise (richer) allows more fuel to enter the engine.

- Idle screw

As you turn the screw clockwise, it increases the carburetor opening at idle and increases idle speed. Turning it counterclockwise decreases the opening and idle speed.

– STEP 1: Low speed needle/idle screw balance

Some racers are making the mistake of setting the idle screw opening too wide [high idle] and setting the engine too rich with the low speed needle!

This will give a false normal idle speed even though the speed is set to high because it "loads up" the engine with excess fuel causing the idle to be lower than set!

If after reving up the completely warmed up engine it tends to idle fast for a few seconds and then drops to a lower idle speed, it means you are making the mistake described above.

Start leaning the low speed needle a little at a time (then repeat the reving up and idle test) and if it takes longer before the idle drops you are going in the right direction!

Eventually as you keep leaning with the low speed needle the idle will stay high, now it is time to lower the idle to get the desired low RPM. Finally richen the low speed needle half turn.At this point if the idle, instead of dropping slowly (meaning you have done the correct setting) starts to increase itself even with the slide valve completely closed, it means you have to richen the low speed needle a little.

– STEP 2: High speed needle

Now that you have the idle set correctly make sure to run the model on the track with a rich high speed needle setting (excessive smoke, blubbering sound).

Start leaning with the high speed needle a quarter of turn at a time till you gain the desired RPM and speed but pay attention the exhaust pipe always emits some smoke.

Do not overheat the engine.

Engine temperature may vary depending on the air temperature, fuel, carburetor restrictor, altitude and driving style: the proper temperature range for PICCO engines is between 85-110 degrees Celsius.

Carburetor link settings

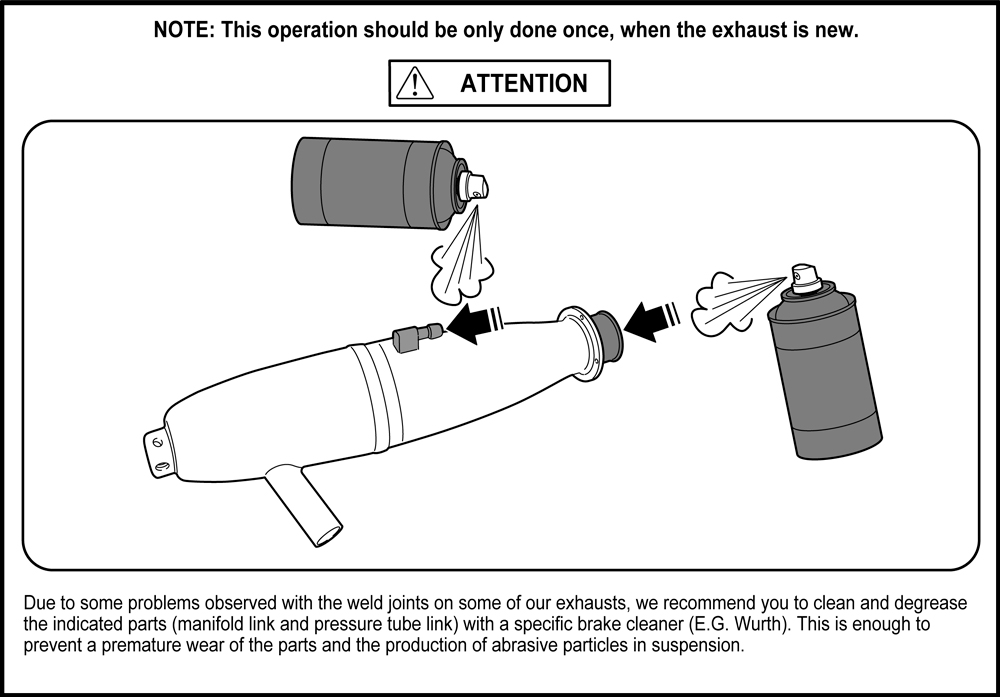

New exhaust maintenance